Sign up for Newsletter

Signup for our newsletter to get notified about sales and new products.

|

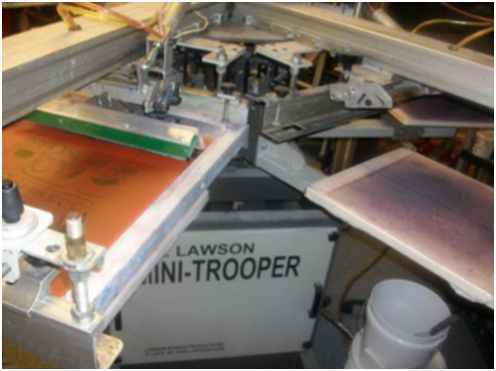

HOW DOES SCREEN PRINTING WORK? The most basic screen printing method will involve making a stencil on a mesh screen, and then pushing paint or ink through that stencil to create the imprint of your design onto the surface of the chosen material (i.e. tees, sweatshirts, hoodies etc.) Any designs that are created with the screen printing method can use multiple shades of ink, however, with a multi-colored design, it is necessary to apply each individual color with a separate stencil. Time for Tees owns an automatic Lawson mini-pro custom screen printing machine operated by the owner, Derrick Messer. There are many reasons why screen printing is a popular technique, but the most compelling of these comes from the extensive choice of colors that can be used. Time for Tees houses hundreds of Pantone colors to meet your specific needs. Another advantage of screen printing is the printer can quickly reproduce a design many times which makes it very effective for creating bulk garments and accessories at a more efficient price. Finally, when an item is professionally screen-printed by Time for Tees, all elements of the process will be done professionally and correctly, including the drying temperature and the correct timings, which will result in a vibrant, long-lasting product that will not wash out. |